What are the main tasks you carried out, and with which results?

My first task was to implement a computational model to predict the device degradation, fabricated through Fused Deposition Modelling (FDM) and then functionalized with a bioactive protein ICOS-Fc (produced and patented by the partner of the GIOTTO project NOVAICOS). The aim of the modeling was to optimize the design of the Device so as to have a controllable degradation and, consequently, the release of the grafted bioactive protein over time and space. In detail, different scenarios for the functionalization were evaluated: (i) external functionalization on the surface of a non-porous device in contact with bone; and (ii) internal functionalization within a device presenting a macroporous architecture with open channels to locally deliver the degradation products. Starting from a hydrolytic degradation mathematical model of polyester-based structures, the model parameters were calibrated for PLLA, which is the main component of the blend filament formulations produced by the GIOTTO partners UNEW. The results showed that the porous geometry (second scenario) would be preferable for a controllable release of the protein over space. However, since the purpose of the device is to increase and ensure the contact between bone and its functionalized surface over time, not to localize the action of the bioactive protein, the first scenario was found to be the optimal case, as erosion of the contact surface (i.e., the diffusion of the degradation products) is slower than in the porous geometry.

Meanwhile, I worked on the optimization of a novel bioprinting platform used to fabricate multimaterial and multiscale scaffolds for bone tissue engineering. Specifically, the platform has two bioprinting units: (i) a FDM tool-head for 3D printing scaffolds with thermoplastic filaments; and (ii) A Drop-on-Demand (DoD) thermal inkjet printhead for depositing biomolecules in specific locations on the printed scaffolds. These bioprinting tools were calibrated in order to be used together, thus allowing different biomaterials and technologies to be combined in one step. The bioprinting platform was validated by fabricating scaffolds for in vitro and in vivo tests, presenting different geometries and material compositions. In detail, cubic scaffolds (5x5x1mm) with 50% porosity and a sealed bottom were fabricated with the blend filaments produced and provided by the GIOTTO partners UNEW. The scaffolds were sent to the GIOTTO partner FORTH to perform in vitro tests by culturing cells in a cyclic uniaxial compression bioreactor for mechanical stimulation.

Furthermore, cylindrical scaffolds (5mm diameter x 0.6mm height) without porosity were 3D printed with PLLA-PCL-PHBV blend filaments. Then, superparamagnetic iron oxide nanoparticles (SPIONs) solutions (produced and provided by GIOTTO partners TECNAN and UCM) were successfully deposited on the top surface with the DoD thermal inkjet printhead, varying the number of layers, i.e., 25 and 50. The 3D-printed functional scaffolds were delivered to the GIOTTO partner UCM for in vitro tests culturing cells in the presence of an externally applied magnetic field to trigger cell mechanotransduction.

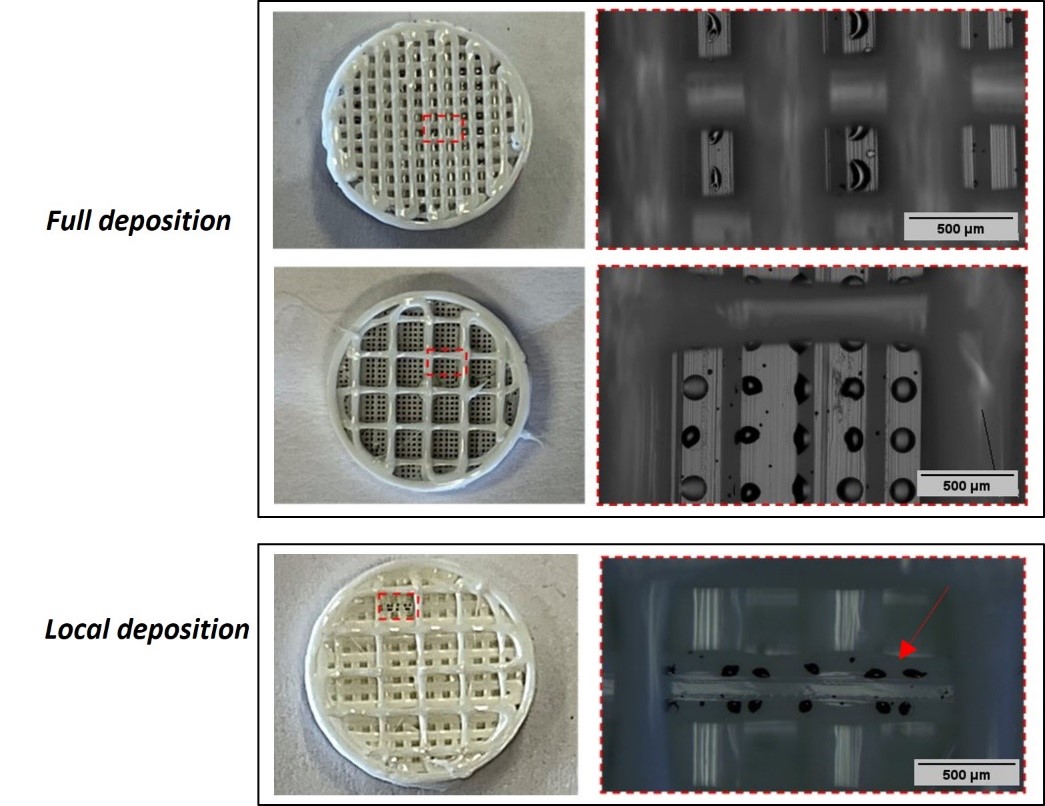

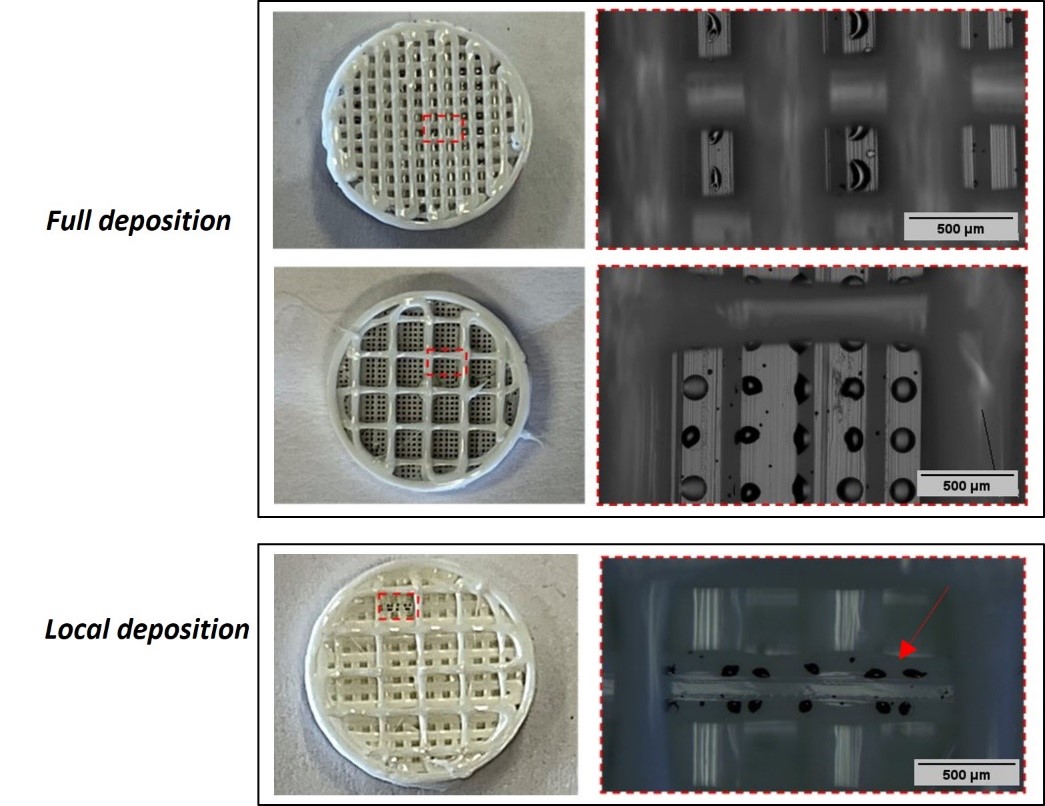

Thanks to the highly calibrated systems, as a proof-of-concept, the possibility to deposit droplets within the scaffold architecture, alternating FDM printing and full/local inkjet, was also demonstrated, which could be useful for isolating nanoparticle action in specific regions of the scaffold.

Next, I focused on setting up, designing, and fabricating a device for in vivo tests on large animals (e.g., sheep). After extensive discussions with GIOTTO partners UNEW and BMI, the device was designed with “C-block” shape that has three circular holes to be placed around a sheep tibia with cerclage wires (a standard fixation mechanism). A crucial point was the device curvature, which had to be similar to the natural bone so as to ensure perfect contact with it. Therefore, starting from CT scans of sheep tibia, the final curvature was set as the average curvature measured in three different regions of sheep bone. Then, the printing parameters (i.e., bed/nozzle temperature, printing speed) and settings (i.e., printing orientation) were adjusted to print it with the novel bioprinting platform. The 3D printed devices were sent to the GIOTTO partner UNEW to be functionalized with ICOS-Fc, sterilized, and then delivered for the in vivo tests on large animals.

Leave A Comment